SGM Magnetics offers a comprehensive range of suspended magnet separators, designed for the efficient recovery or removal of ferrous materials from various industrial material streams. These separators play a crucial role in applications where tramp iron must be extracted from conveyor belts, ensuring improved material purity, protecting downstream equipment, and enhancing overall operational efficiency.

Versatile solutions for different applications

SGM suspended magnet separators are available in multiple configurations to meet the specific needs of various industries:

- Electromagnetic or Permanent magnet versions: Offering flexibility based on operational requirements and energy efficiency.

- Stationary or Self-Cleaning models: Stationary magnets are suited for low-ferrous-content applications, while self-cleaning belt models ensure continuous separation in high-ferrous environments.

- Multiple sizes & configurations: Tailored solutions based on material burden depth, belt width, and processing speed.

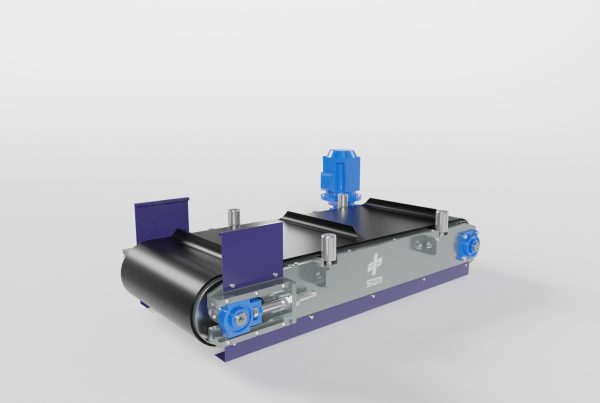

SGM suspended magnet separator models

SGM offers a range of suspended magnet models to suit different industrial needs:

- DNE (Electromagnetic, Self-Cleaning): Designed for maximum magnetic field strength and separation efficiency, featuring a rugged carbon steel frame and self-cleaning discharge system.

- DNP (Permanent Magnet, Self-Cleaning): Features a semi-closed magnetic circuit with high-intensity magnet blocks, ensuring strong attraction and efficient separation.

- DBE (Electromagnetic, Stationary plate): Ideal for low-ferrous-content applications, offering a compact yet powerful design for effective tramp iron removal.

- DBP (Permanent Magnet, Stationary plate): A low-maintenance solution for continuous ferrous separation, built with durable magnet technology for long-term performance.

Optimized for industrial performance

- Precision-engineered magnetic circuits: Maximizing separation efficiency for different ferrous particle sizes and shapes.

- Robust & durable construction: Designed to withstand harsh industrial environments.

- Customizable installation options: Can be mounted above conveyor belts or head pulleys to optimize separation efficiency.

- Optional features: Including RPM belt sensors, buffer stop sensors, and outdoor protection kits for enhanced functionality.

With a strong track record of innovation and industrial expertise, SGM Magnetics delivers high-performance ferrous separation solutions, ensuring higher metal recovery rates, reduced maintenance costs, and improved process efficiency across various industries.

How it works

Belt suspended magnet separators are ferrous separators positioned either above a conveyor belt on which the material to process travels or above its head pulley depending on the application. The magnet separator is provided with a belt for the discharge of the attracted ferrous from the steady magnetic part of the separator. The magnetic part of the separator can either be made of some electro magnet windings or permanent magnet blocks.